WE GUARANTEE

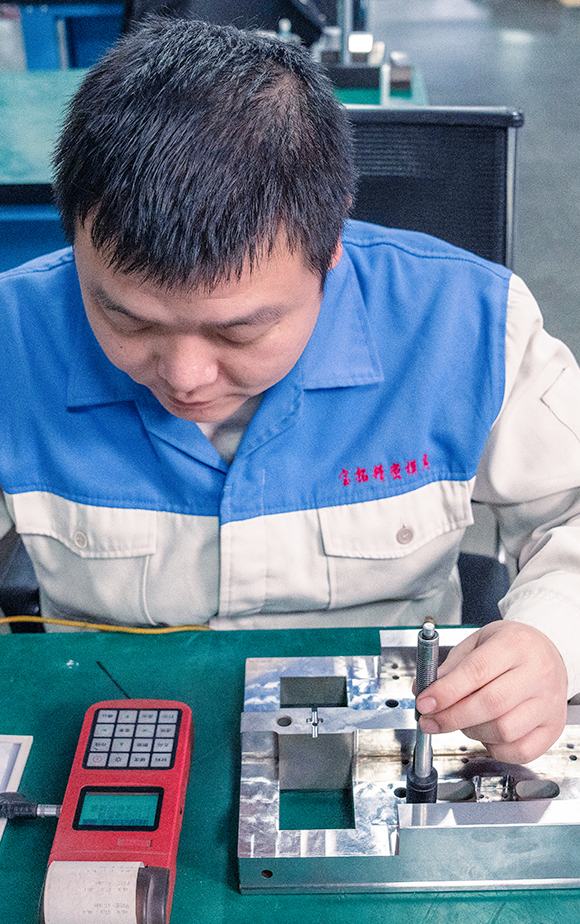

Bring Your Idea Into Reality,No detail will be missed, never .When a sample is compBaotuo quality inspection department is composed of experienced quality professionals and dedicated employees. We implement strict quality standards and inspection procedures (including raw material quality inspection, product processing quality inspection, and finished product quality inspection) to ensure that we provide products that meet your needs. Quality parts on demand and spotting problems before you do, allowing us to correct problems immediately.leted, we will check every detail with your original design and requirements to ensure it is what exactly you want.

After the workmanship inspection and all details are checked again, we bring your idea into a reality and will send you as soon as you expect.

RAW METARIAL INSPECTION

The choice of material has a direct impact on the quality and lifespan of injection mold components, while also determining the appearance and intrinsic quality of molded plastic parts.Therefore, we conduct rigorous inspections of raw materials.

1,Distinguish the color and marking of raw materials

MANUFACTURING INSPECTION

Our professional team dedicated to providing high quality products and services to customers.Below are our main quality inspection items in the whole production process.

Material incoming: 100% inspection

PRODUCT INSPECTION

Most of the equipment in the lab is imported from abroad. And we strictly follow the process to make the maintenance. Measurement of the exact data of production: For machine products data of length, width, thickness, inner diameter, diameter and groove width, we have TESA 700, which made in Switzerland.For 2D dimensions like the plane, step, depth, and so on, we use image measurement apparatus made in Taiwan

SECONDARY INSPECTION

From the meticulous selection of raw materials to every step of the production process, and finally, the presentation of the end product, we approach each stage with precision. After the completion of each process, our reinspection team conducts a thorough examination to ensure that every connector mold parts is flawless and impeccable.

RESOLVING QUALITY ISSUES

Should your order not meet specifications, We will be able to raise any issues as soon as possible. Our order fulfillment team will resolve these issues as quickly as possible, typically within 1-3 business days.

GET YOUR PARTS INTO PRODUCTION TODAY

Copyright© 2023 BaoTuo. All Rights Reserved.

We will contact you with in 24 hours.